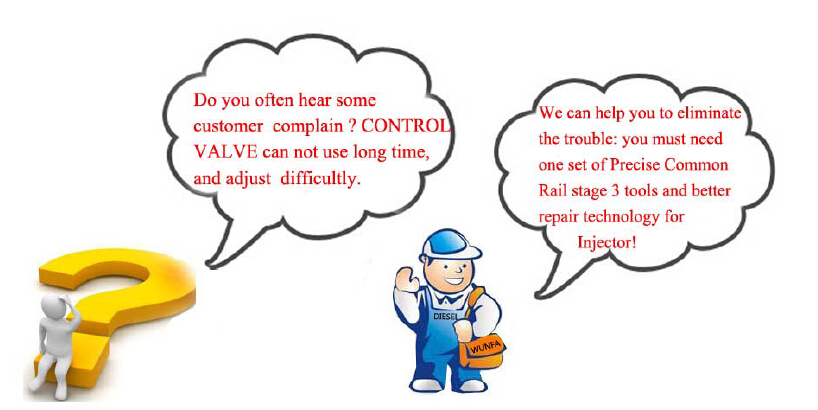

During repair process of the common rail injector, the most important adjust shim is Armature Lift Shim.

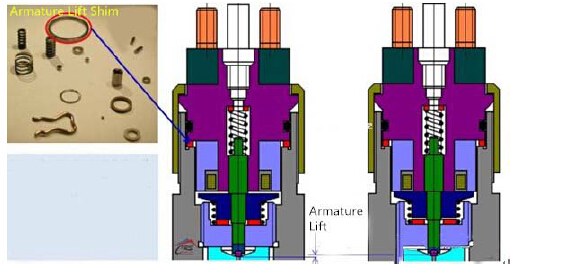

Cavitations Erosion: During the working process of injector, the fuel is running on high speed and high pressure, to hit to the ball seat surface on high

frequency, then metal surface is damaged by such contact with the fluid like the pictures above.

2.Simple adjusting way

After you change valve set, if the Emission point (TL) is lower, idle speed (IL) is lower, how to adjust? Simple way of adjusting shim is the following:

Emission point is lower: Thinning Thickness of solenoid valve spring shim (B13-WUNFA CODE) Idle speed is lower: Thinning Thickness of nozzle spring shim (B14-WUNFA CODE)

But if you use this way, you must ensure that the Armature Lift is within the correct range of tolerances setting, if the Armature Lift isn’t inside the range, this injector cannot work well; If the Armature Lift in Upper Tolerance range, this injector can work, but only can be used for short time and then leakage become too much, which is caused by CAVITATION EROSION of ball seating contact surface.

Best choice is choosing the Down limit thickness of armature lift (which must be in tolerance too), as thinnest is best, so chose the thinnest Armature Lift shim (B22-WUNFA CODE) according the Stage 3 tools instruction.

3.Engine factory Laboratory Test Report

Test sample: Complete new original BOSCH injector 0 445 120 081 30207/0362

What is the most suitable range of Armature Lift for injector good injecting performance? We do the following experiments to share with you。

Testing process:

1.Testing the original injection quantity of 0362 on Full load (VL)、Pre-injection(VE)、Emission point(TL) and idle speed point(IL);

2.Remove the solenoid valve, adjusting the thickness of Armature Lift shim, shim thickness is 5 μm for one grade, respectively, thickening and thinning on each 30μm. That is, the Armature Lift setting values are set to 22, 27, 32, 37, 42, 47, 52, 57, 62, 67, 72, 77, 82μm on different time.

3.When changing the thickness of armature lift shim every time, need to reassemble and testing the oil quantity of each rated point on the test bench, totally test 13 times.

Summarizing all the oil quantity point changes trend along with the Armature Lift change Note: In this experiment, only adjust Armature Lift value,other all shims are forbidden to adjust.Experiment Result:

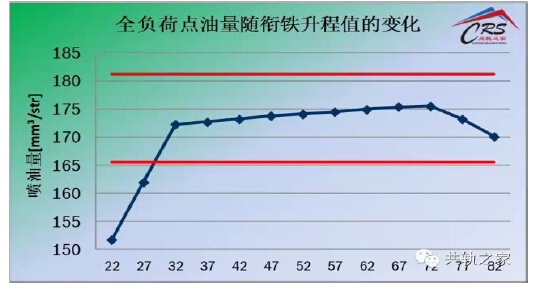

Full load point(VL) [1600bar,2000µs], oil quantity change chart along with Armature Llift value change.

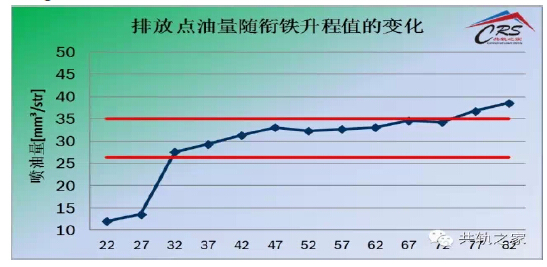

Emission point(TL) [1000bar,600µs] , oil quantity change chart along with Armature Lift value change

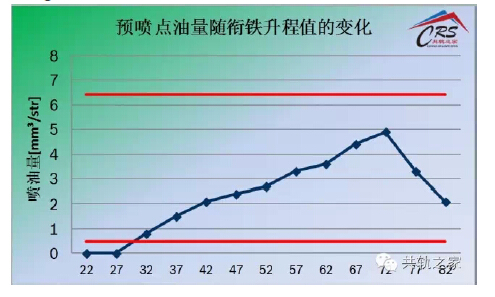

Pre-injection point (VE) [1000bar,250µs] , oil quantity change chart along with Armature Lift value change

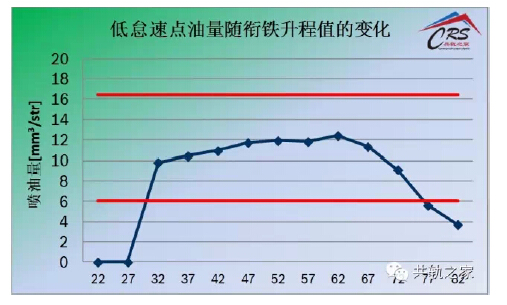

Low idle speed point(IL) [250bar,1000µs] , oil quantity change chart along with Armature Lift value change,

Analysis of experimental results:

1.The effect trend of Armature Lift on different checking points is not the same;

2. Armature Lift more or less will due to injector abnormal injection;Normally,to Bosch original valve set,when Armature Lift is between30~70μm, the injector can have good injecting performance.

Alternative valve set, because the level of processing difference, only when Armature lift is within a very narrow range, the injector can inject perfectly.

Here we remind you, If you want to ensure the perfect injection, Armature Lift should not be too big, because if the Armature Lift is too big, the risk of cavitations Erosion on the valve seat surface will increase, and this will due to injector oil return quantity being larger in a very short time.

But how to chose the exactly and most suitable Armature Lift shim is a serious job, because different injector has different suitable thickness of Armature Lift value. So please choose WUNFA IRIS stage 3 tools or BOSCH original stage 3 tools to do such repair, and then you can get the perfect injection performance and long time using life. Then you no need worry about customer compliments on Heavy smoke, High fuel consumption, Knocking sound of cylinder, and no need worry about the short time using life of control valve which you repaired.

WUNFA IRIS stage 3 tools: 40 minutes for 1 injector complete disassembling, checking and assembling. BOSCH stage 3 tools: 4 hours for 1 injector complete disassembling, checking and assembling.